mcmuffins and half bridges

1/30/2015

Things you can do with a MoTeC Dual Half Bridge:

The MoTeC dual half bridge is a pretty neat device. Simply put, it allows you to drive reasonably large, variable speed motors, directly from the ECU. Why do you care about this? I’ll tell you why, because the world isn’t as simple as “ON” or “OFF”.

The DHB is effectively a solid state relay that can take a low current PWM (pulse width modulated) signal (driven low or high) from an ECU or a Dash and drive a very high current (20A continuous, maximum) motor at varying speeds or positions. There are a number of different cool circumstances where you could use a DHB to your advantage. I’ll run down a few below:

Example 1:

We’ve all heard that car. You know the car I’m talking about. The car with the big ass radiator fan that sounds like a jet is about to take off. I find that so annoying. No one needs a loud ass fan to turn on for 60 seconds just to cool your radiator off, so that it can turn back on again, 2 minutes later.

For instance, when you go to order your favorite McBreakfast from the McResturant, you don’t pull up to the window and scream at the top of your lungs “I WANT A MCMUFFIN”. You say, “I want a mcmuffin, please”. Your radiator fan is screaming “I WANT A MCMUFFIN” every time it turns on full blast for no particular emergency. Drives me nuts.

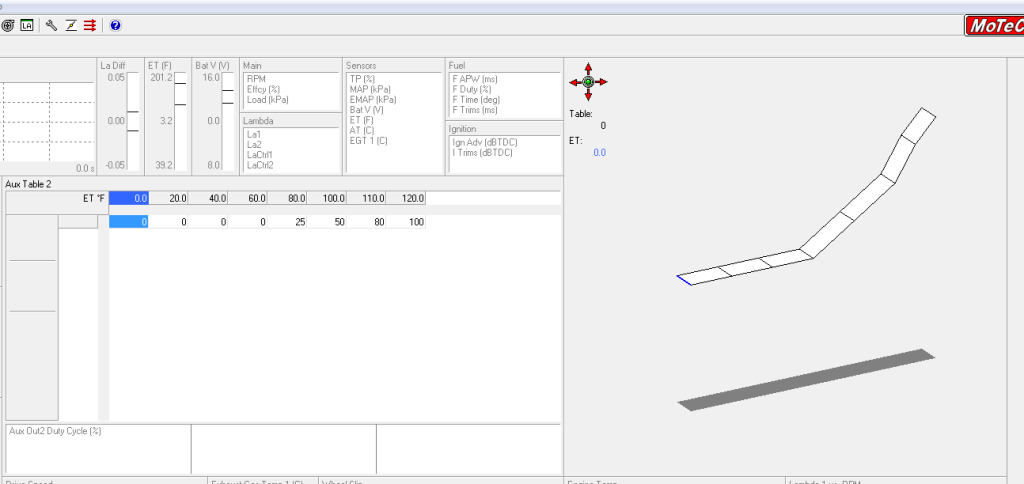

So the DHB can fix this problem. The DHB can do the high current work of fan speed control. All ECU’s that are worthwhile will allow the user to create a PWM output table based on user definable axis. So then just create a table that looks like this:

You’ll have coolant temperature on the X-axis and the values in the table will correspond to fan duty cycle (or speed). As temperature increases, so will fan speed until it gets to the point of being at full blast. The thing to note, is that it will only be turning at full speed (and screaming about the MCMUFFIN) if it NEEDS to be there. Cool.

Example 2:

Say you’re an R35 GTR owner, or a Supra owner, or a huge power engine owner, and you have 3 fuel pumps to supply your daily driven 1000+ hp engine. If you have 3 fuel pumps running at all times, you’re wasting energy in two ways.

-First, you’re going to waste a ton of electrical energy. Figure worst case scenario your pumps draw 20A each.

-3 fuel pumps. 20A a piece (average worst case scenario for your average 340-400LPH pump)

-20A times 3 pumps = 60A. Figure 13 volts while the engine is running. Amps times volts equals watts. So, 60 * 13 = 780 watts of power to drive your three fuel pumps at idle. If you’re like most in the US, watts don’t really mean much to you in an automotive world.

(sidenote of relevance) the Kilowatt is used to measure Horsepower in other parts of the world.

-However, for this example, it is relevant.

1 watt = 0.00134 horsepowers

So after doing some simple math, we can figure that those three fuel pumps are taking a total of ~1 horsepower to drive. That’s crazy. You don’t need that when you’re idling!

-Secondly, you’re going to heat up the fuel excessively. Fuel pressure regulators are just like any other regulating valve, they restrict the flow so that pressure can increase, and they allow less restriction so that pressure can decrease. The variability is based off of manifold pressure / vacuum (that’s what that hose from your intake manifold to your fuel pressure regulator does!).

So now think about your fuel pumps trying to force the maximum volume of fuel that they can flow through a tiny regulator and fuel injectors that are barely opening (because you’re at idle). This is a strain on the pumps, and when there is strain, there is heat. This heat will eventually be transferred in to your fuel system and you will watch your fuel temperatures steadily rise. Hot fuel isn’t so good, but not totally deadly. What can be bad is that if your car was tuned on a dyno with cooler fuel temperatures, and then you go out and drive your car around the city for an hour and then have a blast on a local highway, you might find that your mixtures are slightly leaner due to fuel density changes relative to heat. (Injector dynamics wrote a really great article about this, it’s short, and to the point injectordynamics.com/articles/injector-dynamics-newsletter-feb-2013/ )

Ok, now we know that running your fuel pumps at full bore all the time maybe isn’t such a great idea. Now what do we do?

What if you could slow down your fuel pumps at idle and part throttle conditions? What if you could have them speed up as you creep in to boost?

You can!

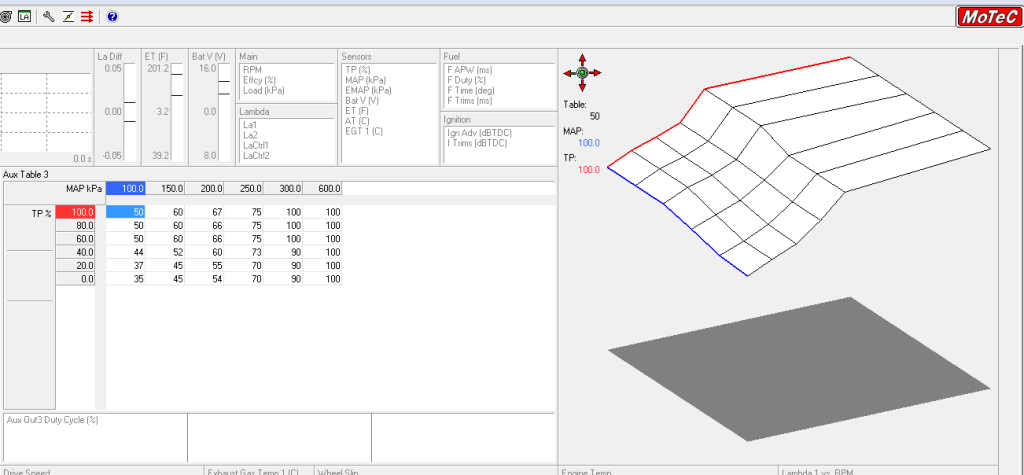

All ECU’s that are worthwhile will allow the user to create a PWM output table based on user definable axis. So then just create a table that looks like this:

(Sidenote of relevance: Even this table is over complicated. You can just have this referenced to manifold pressure without TPS, I just think it’s neat to be able to change the speed up relative to TPS too)

The DHB can take this small current control output from the ECU and drive the heavy current fuel pump with it. So when you’re on the throttle 100% at 0 manifold vacuum, the fuel pump duty cycle will be 61%, and will gradually increase to 100% by the time you reach 175kpa (a little less than 30 psi of boost).

Use your parts efficiently!

Shameless plug is that I usually have one of these around for sale, this moment in time is no exception. Email me if you’re interested in hearing more about it, or just want more of my rants. sander@obsidianeng.com