you should really know what you’re doing.

11/16/2015

We’re not all born with knowledge. We’ve got to work for it.

I guess I could have entitled this post “really useful stuff you can do with a simulator”, but I think that the current title is equally effective.

A long while before this current moment, most of my pre Obsidian Motorsport Group professional life was based around figuring out problems. (I promise that I’ll try and keep the retrospective of my younger self to a minimum). I started my automotive life as a sophomore high school kid working at an automotive repair shop. They did general repair and specialized in fixing old air-cooled VW and Porsche engines. Looking back on that job, I think that it really gave me a solid foundation for my professional life (and arguably my personal life, too), but at the time that I was there, I hated it.

The reason for all of my misplaced adolescent hatred was based around the idea that my bosses (two guys) wouldn’t ever allow me to just replace a part to see if the problem got better. They required me to prove that every part I replaced, needed to be replaced. If that involved showing them there was a definitive dead short in a harness with an ohm meter, or showing a oscilloscope capture of an M112/113 Mercedes crankshaft position sensor as it loses its amplitude when the sensor gets hot. Again, hated it at the time, but it really beat in to my brain that it’s best to prove your hypothesis before jumping to a conclusion.

(…I just had a great idea)

Fast forward to now, the mindset of proving your actions with quantitative data is really the basis of what I’m trying to demonstrate the power of.

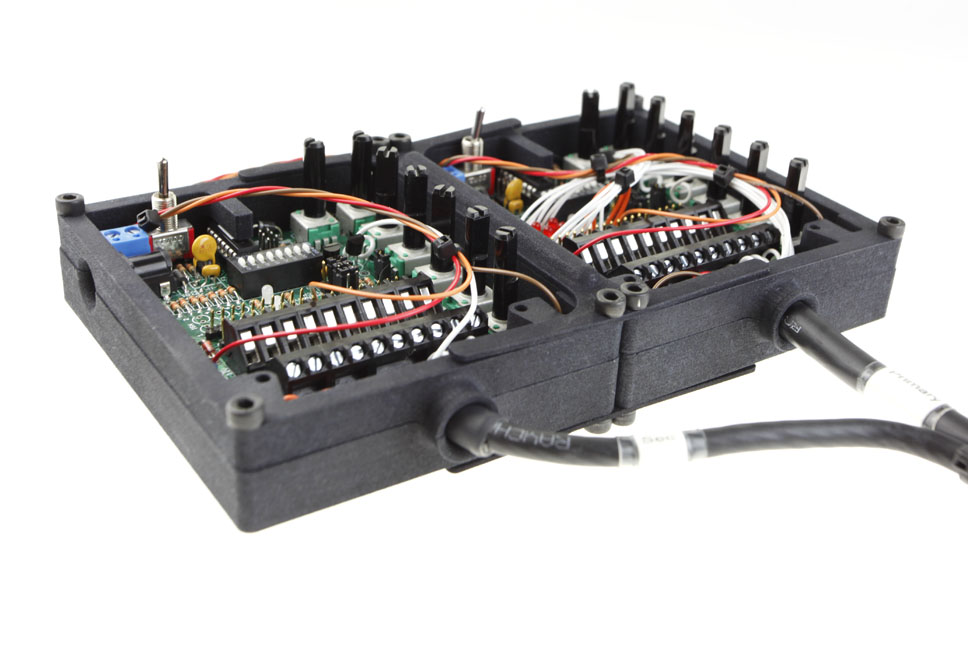

Here are some basic examples of things that are made easier with a simulator:

Do you know how the VE model works?

Fueling is (for me, anyway) one of the more interesting variables in an engine management system to wrap ones head around. As a basic recap, fuel injector pulse width is the output of an equation inside an ECU taking in to account a number of different sensor values. IPW is the amount of time that the ECU commands the injector to be open. The amount of fuel that is delivered from the injector during this on time is based on fuel pressure, measured injector flow rate, battery voltage, and density.

The following truth is unfortunate: You don’t need to know about any of that stuff (or the ideal gas law) to tune an engine mostly well with newer volumetric efficiency based ECU’s

You can pretty much input a few simple variables and set the VE table to 90 and the engine should start up and run mostly well.

So perhaps being ignorant of the ideal gas law or what determines injector on time, figure you’ve bumbled through the map enough to get the car running pretty solid and making a “number” for the customer. Great. Good for you. Say the customer comes back and wants you to install a flex fuel sensor and re-tune for E85 or E98 or something of the sort. Are you confident that the ECU is going to add the appropriate amount of fuel over your pump gas tune when you go to make that first dyno pull on E85? What about using multiple ignition tables? Do you know that the blend table is going to work correctly? What happens if your VE table is only scaled out to 20 psiG, and you have a run out to 25 psiG, what’s the ECU going to do if you ride off the end of the table?

That can all be simulated, on your desk while you’re sitting in your favorite thinking chair.

Beyond the initial benefit of just seeing what’s going to happen to the injector pulse if you add in some ethanol content or drive off the end of the load axis, you can spend the time to reverse engineer the fuel model that is being used in the ECU. I may be a bit of an outlier in this department, but I try not to trust or have faith in anything I don’t understand or haven’t tested, first.

What about fuel compensations / trims?

Not all ECU’s are created equal in this department. How do you know if the ECU uses a multiplier or a percentage value? You would think that this would be easy to find in some ECU software programs, but it is not always as easy as one would think. It’s a lot more relaxing to do that with a simulator and move independent values around to see how it is affected before you get to the dyno / track.

Are these the same? (Emtron and MoTeC)

(picture will be replaced, soon)

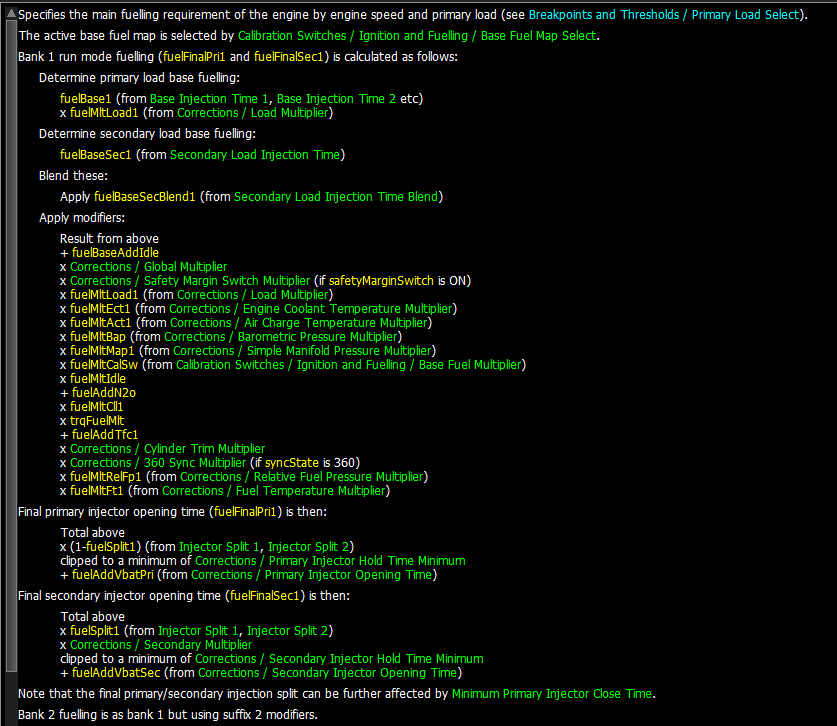

I should take a second here and give an honorable mention to Life Racing’s LifeCal. They have an awesome, easy to read layout of the entire fuel calculation. See picture below:

What about secondary injection / blend tables?

Not all ECU’s are created the same here, either. Some of the wording is a little opaque on the Mx00 MoTeC ECU’s when it comes to secondary injection

What about boost control?

If you’re the type of guy or girl who just likes to “let it eat” with open loop wastegate duty cycle controls, then this probably doesn’t matter much to you.

However, if you take pride in what you do and find a need for precise boost control, getting a feeling for the PID sensitivity controls is much more relaxing at home with a cup of coffee or any other preferred beverage of choice. PID settings are ECU manufacturer specific. Settings that work in an AEM V2 / EMS4 box WILL NOT work in an MX00 MoTeC ECU and vice-versa.

What about traction control?

Yes. This is where simulators are pretty great. The MoTeC M800 ECU’s have awesome traction control settings. The power of the M800 is the ability to make tables and compensations acting on other tables or compensations. After you get through a few levels of that, it can get a bit heavy to wrap your head around. So if you are using one of the Intermediate or Advanced simulators, you can simulate a driven wheel speed to see what’s going to happen with the timing, drive by wire throttle, fueling, or limiters BEFORE you get to the track. If you take a second to think about all of the time that can save you, it’s pretty immense.

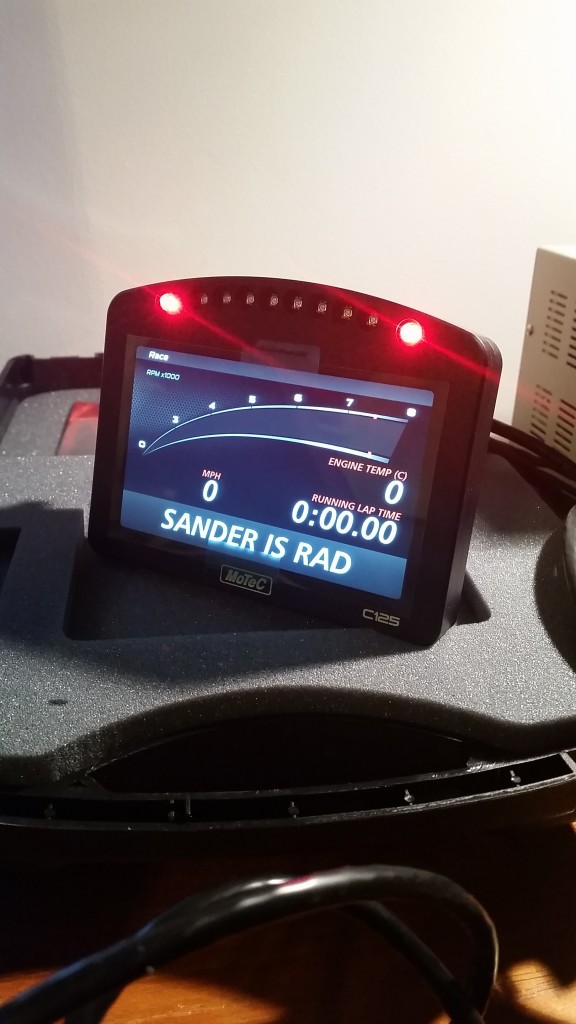

What about setting up CAN devices to talk to each other?

You CAN do that pretty easily (I know, I’m hilarious). CAN stuff isn’t bad to do if you’re using all MoTeC products, as they provide really easy to set up templates. However it CAN get a BIT (sorry, I’ll really stop now) more difficult if you’re using MoTeC dash loggers and an AEM ECU (or Cosworth ICD and a Bosch Motorsport ECU or any number of other combinations) If you wanted to utilize all of the CAN data sent over from the AEM ECU, you would have to write a custom can template. This is not too bad to do if you can simulate values (say RPM for instance) in to the AEM ECU, connect the MoTeC dash to the AEM ECU via CAN and then work on the scalars and multipliers until the value is correct in the MoTeC dash.

So, why did I start this post by talking about myself as a young all-knowing teenager? Because I used to think that it was stupid to have to prove your work. If I could get the car fixed by guessing and maybe getting lucky, then that was good enough. The truth is that it’s really not good enough. If you can get by moving numbers around and making some power and you’re ok with that, then great. Although, I think that what’s going to separate “tuners” from professionals is knowledge and understanding. Buying a simulator isn’t going to give you the knowledge and understanding, but it can help you gain it much easier and much more safely. (and, it’s entertaining if you’re easily entertained).